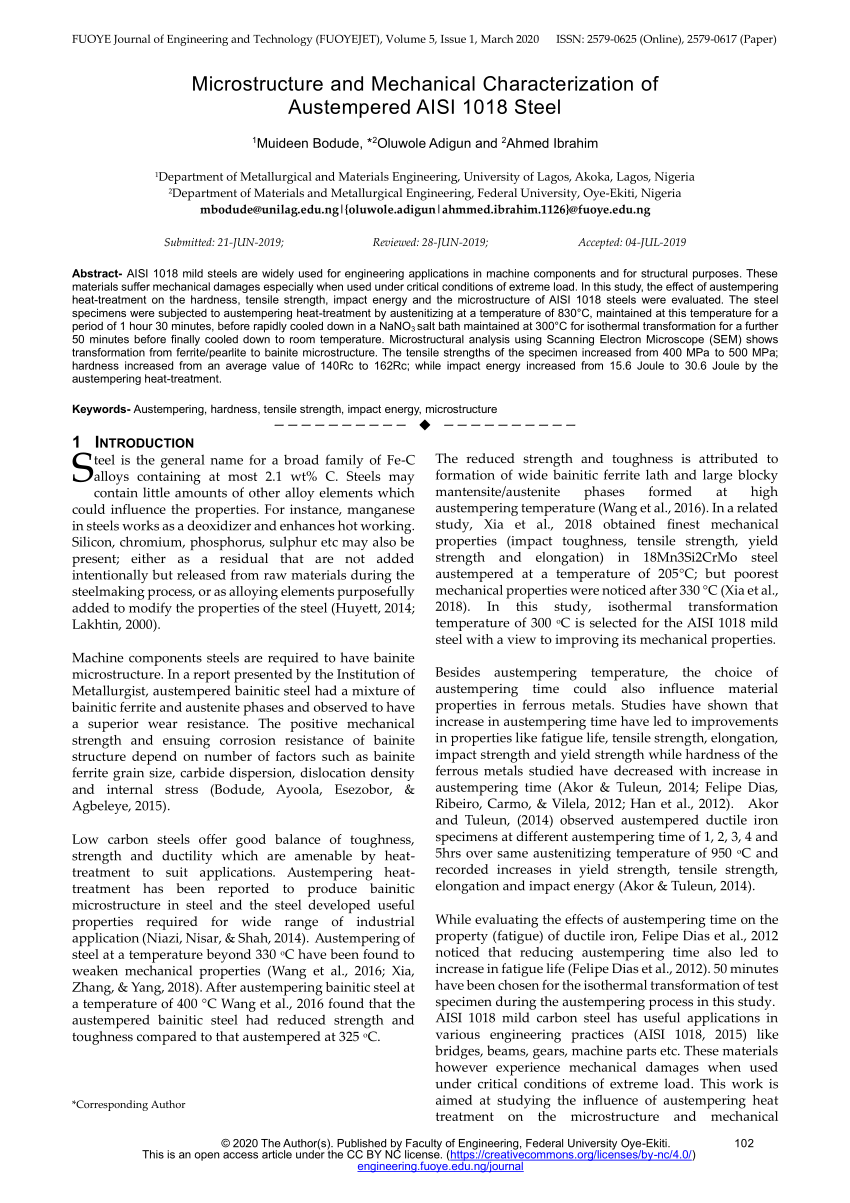

Manufacturer of C1018 STEELCOLD ROLLED FLAT BAR available in a number of sizes to suit your application needs, request a quote or place an order with Metal Supermarkets today CALL US TOLL FREEDensity 787 g/cc 0284 lb/in³ Mechanical Properties Metric English Comments;1018 Cold Roll Steel C1018 is a general purpose low carbon steel with good case hardening qualities It has a higher manganese content than certain other low carbon grades, such as 10 With higher manganese, 1018 is better steel for carburized parts, since it produces a harder and more uniform case It also has higher mechanical properties

Basic Descriptions Of Making Carbon Alloy Stainless And Tool Steel P 4 Carbon Grades Types And Numbering Systems Glossary P Pdf Free Download

C1018 steel mechanical properties

C1018 steel mechanical properties-Mechanical Properties Brinell = 126, Tensile = 64,000 /, Yield = 54,000 / Alloy 1018 is the most commonly available of the coldrolled steels It is generally available in round rod, square bar, and rectangle bar It has a good combination of all of the typical traits of steel strength, some ductility, and comparative ease of machiningDespite its unimpressive mechanical properties, this steel alloy is easily formed, machined, welded and fabricated It is especially suited to cold forming and bending operations 1018 steel is suitable for parts which require cold forming (such as crimping, swaging, or bending)

2

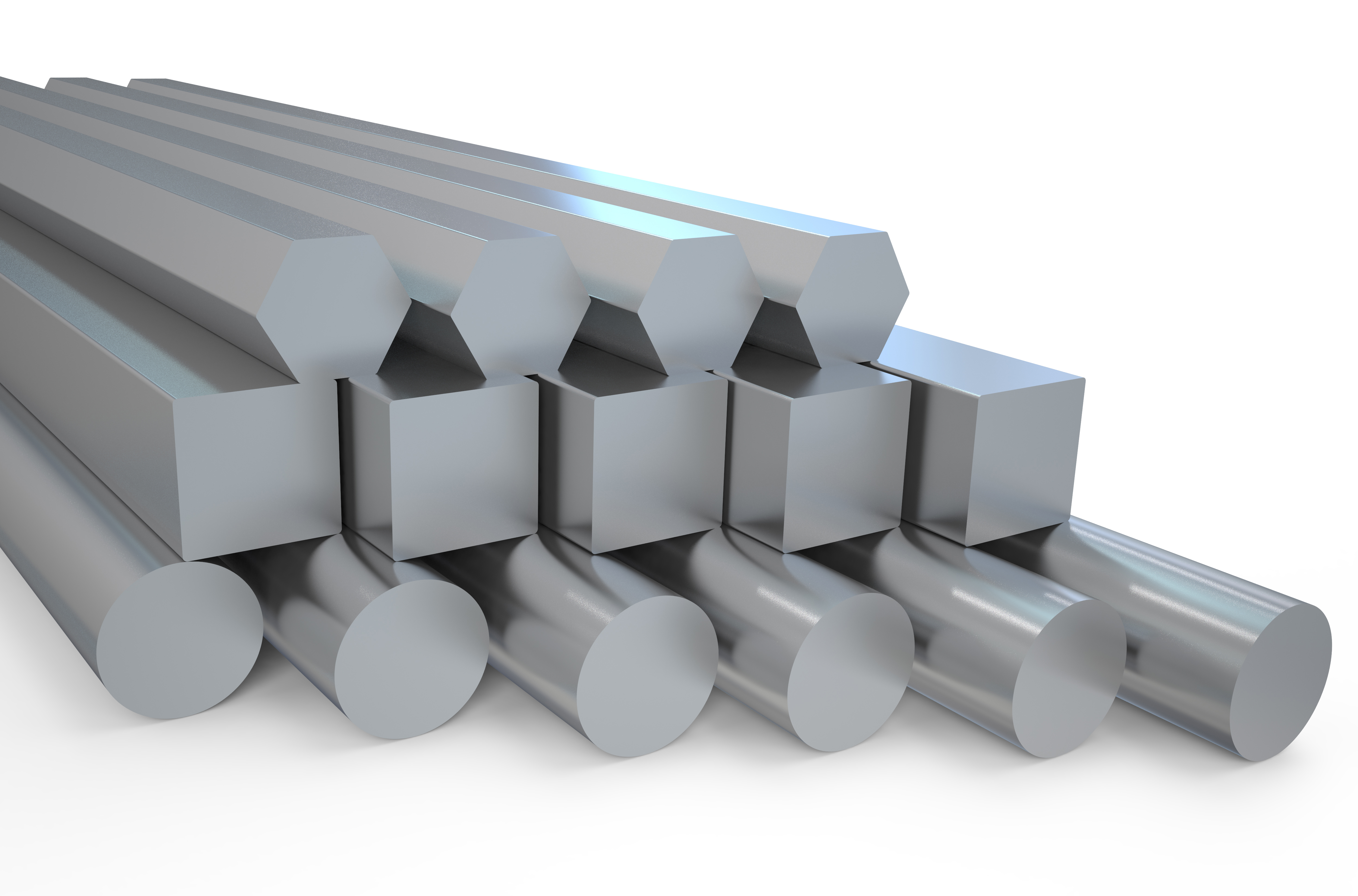

1018 Mild Steel 1018, 10 (HR,CF) Low carbon steelHas good hardening properties, fair machinabilityReadily brazed and weldedAlloy 1018 is the most commonly available of the coldrolled steels It is generally available in round rod, square bar, and rectangle barC1018 Cold Finished Round, aka CRS Round or Cold Roll Round Bar is a steel product with closer dimensional accuracy, tolerances, and smoother surface finish than hot rolled barC1018 Cold Finish Round is a general purpose low carbon steel with good case hardening qualities and is especially suited for cold forming and bendingCold Rolled Steel C1018 Grade Summary C1018 is a general purpose low carbon steel with good case hardening qualities It has a higher manganese content than certain other low carbon grades, such as 10 Cold Rolled C1018 is better steel for carburized parts, since it produces a harder and more uniform case

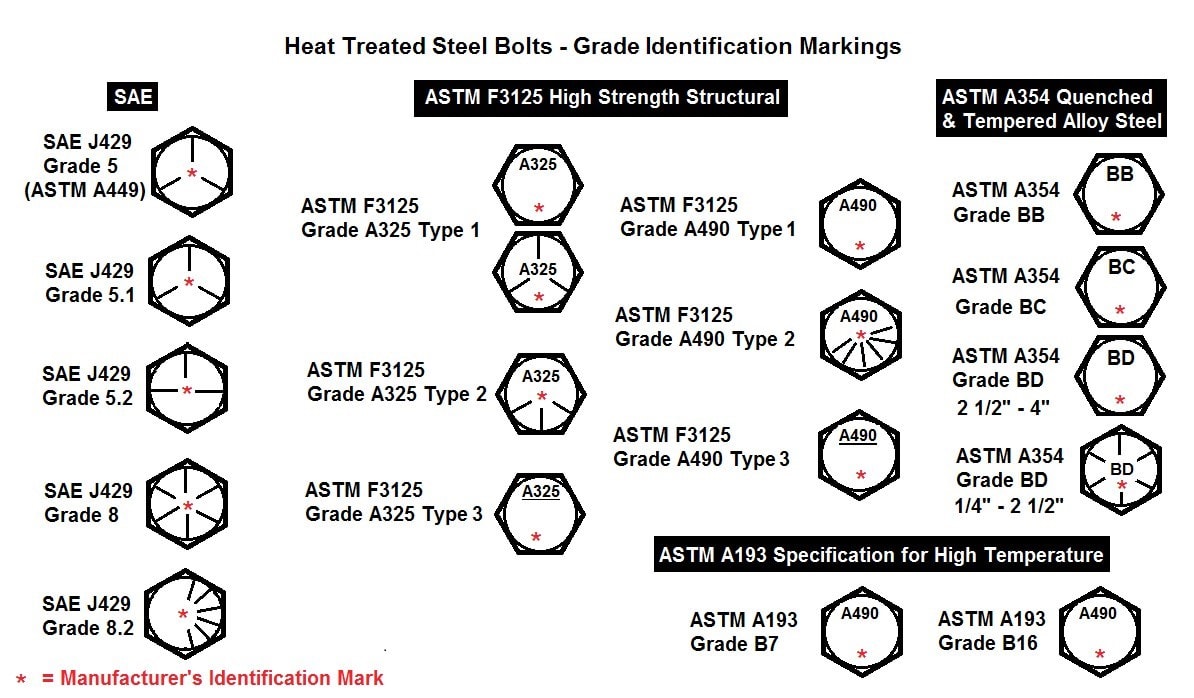

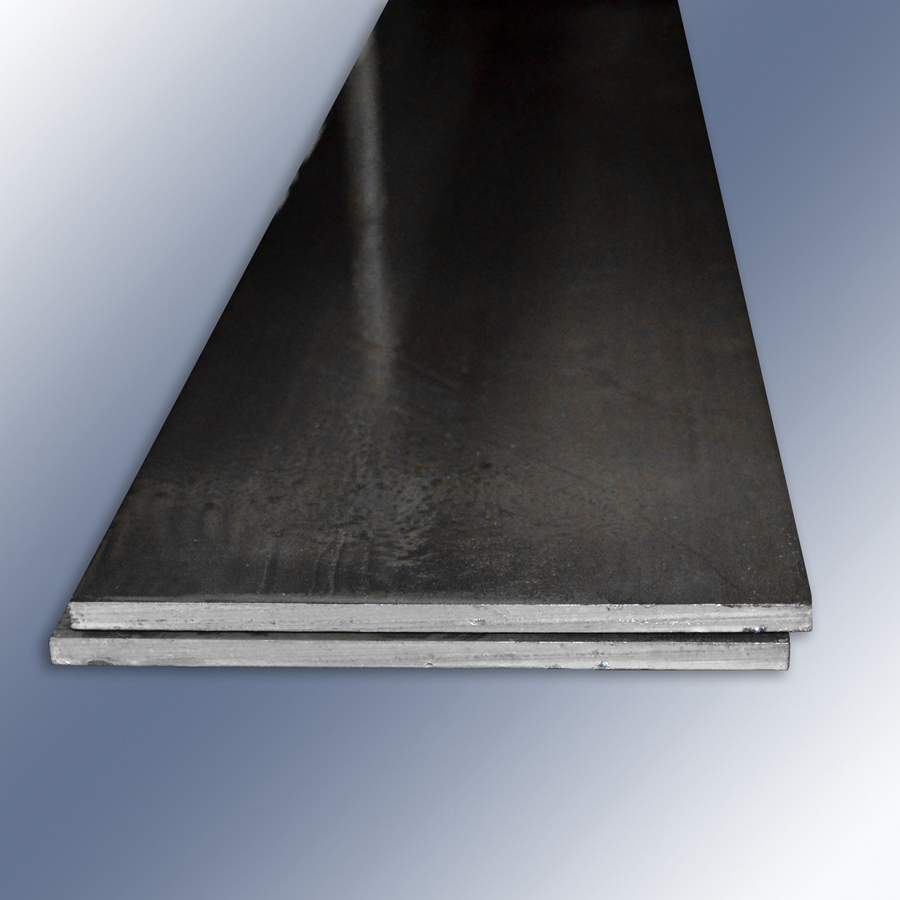

1018 Cold Finished Flat C1018 Cold Finished Flat, aka CRS Flat or Cold Roll Flat Bar is a steel product with closer dimensional accuracy, tolerances, and smoother surface finish than hot rolled bar C1018 Cold Finish Flat is a general purpose low carbon steel with good case hardening qualities and is especially suited for cold forming and bendingAISI 1000 Series Steel ;AISI 1081 grade has low carbon steel content Up to 025% carbon You can buy all types of AISI 1018 Nuts, AISI 1018 Bolts, AISI 1018 Screws, AISI 1018 Washers for ideal connection & captious applications To get a free quote and a quick response call us Top Carbon Steel AISI 1018 Spring Washers, AISI 1018 Threaded Studs, AISI 1018 Allen Head Socket Set Screws, AISI 1018 Steel

1018 Cold Finished Most cold finished bars are produced by cold drawing oversize hot rolled bars through a die The cold reduction of the bar results in significantly improved mechanical properties, with a smooth surface finish to close tolerances The cold working of the bar likewise improves machinability, usually rated at 76 SAE 1018 carbon steel is commonly used in high volume screw machine parts applications UNS Number G Ok let's start with SAE 1018 Chemical Composition Chemical Composition C, Carbon 015–0 Mn, Manganese 060–090 P, Phosphorus max 0040 S, Sulfur max 0050 Learn more about Chemical Composition Now it's the mechanical propertiesChoose from our selection of grade 1018 steel products in a wide range of sizes Includes material certificates and CAD models In stock and ready to ship

2

2

Information,mechanical properties, physical properties, mechanical properties, heat treatment, and Micro structure, etc It also contains the use of 1018,such as it is commonly used in bars, sheet,plates, steel coils, steel pipes,forged and other materials application Datasheet for Steel Grades Carbon Steel 1018 1018 Standard NumberSteel Grade Equivalency A633 Gr A,C,D 09 max Comparative designations of grades with similar composition from other important standards Unified Numbering System (UNS) is an alloy designation system widely accepted in North America American Iron and Steel Institute (AISI) standards for steel compositions European standardsLow Carbon Steel Material Notes Medium low carbon steel, has good weldability and slightly better machinability than the lower carbon steels

080a15 1018 Bright Bar En3b Engineering Steel Impact Ireland Metals

Order 0 25 Mild Steel Square Bar 1018 Cold Finish Online Height 1 4

AISI C1018 steel (1018 CRS) has good weldability, surface hardening quality, higher mechanical properties and better machinability Cold drawing increases tensile strength, yield strength, torsional strength, surface hardness and wear resistance, but reduces ductility ASTM AISI SAE 1018 hot rolled steel is also known as 1018 HR, and has good toughness, strength, ductility,Alloy 1018 is the most commonly available of the coldrolled steels It is generally available in round rod, square bar, and rectangle bar It has a good combination of all of the typical traits of steel strength, some ductility, and comparative ease of machining Chemically, it is very similar to A36 Hot Rolled steel, but the cold rolling process creates a better surface finish and better propertiesHome value report for 1018 Garnet Ridge Ct, Las Vegas, NV 123 View on Homescom as well as property record details, price history, local schools and refinance offers

7 Things To Consider When Choosing A Carbon Steel Grade

Difference Between A36 Vs 1018 Steel Surprising Answer

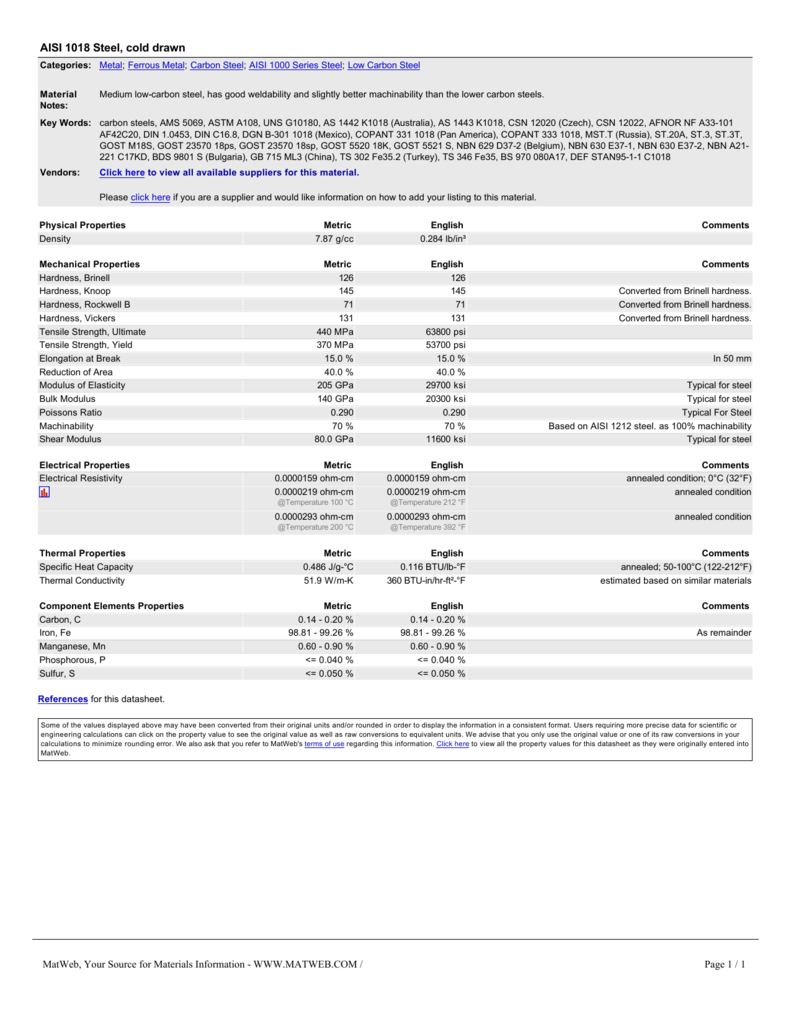

AISI 1018 Steel, cold drawn Key Words carbon steels, AMS 5069, ASTM A108, UNS G, AS 1442 K1018 (Australia), AS 1443 K1018, CSN 1 (Czech), CSN 122, AFNOR NF A AF42C, DIN , DIN C168, DGN 01 1018 (Mexico), COPANT 331 1018 (Pan America), COPANT 333 1018, MSTT (Russia), STA, ST3, ST3T, GOST M18S, GOST 18ps, GOSTASTM SAE AISI 1080 High Carbon Steel ASTM SAE AISI 1080 steel is a high carbon steel with a carbon content of 0750% This article summarizes the 1080 carbon steel chemical composition, physical properties, mechanical properties, heat treatment and applications, etcC1018 Cold Finish Flat Bar is a low carbon general purpose steel It is one of the most abundantly available metal grades C1018 Cold Finish Flat, is a rolled steel product with close dimensional accuracy, smooth surface finish, and increased mechanical properties and machinability This metal can easily be formed, machined and welded

Quality Cut To Size Cold Rolled Mild Steel Hexagons Supplier In Los Angeles Ca Usa Bobco Metals

The Evolution Of Lpr Curves Of C1018 In A 1 Nacl 40 C B 1 Download Scientific Diagram

Physical Properties Metric English Comments; Cold drawn SAEAISI 1018 is SAEAISI 1018 steel in the cold worked (strain hardened) condition The graph bars on the material properties cards below compare cold drawn SAEAISI 1018 to wrought carbon or nonalloy steels (top), all iron alloys (middle), and the entire database (bottom)STEELCOLD ROLLED Cold rolling increases the strength and hardness and decreases ductility of steel by rolling it at ambient temperature (or below its recrystallization temperature) In addition to improvement of mechanical properties, the cold rolling produces steel plate/sheet of the desired physical dimensions

Galvanized Carbon Steel Keeps You Safe In The Rain Ulbrich

A 36 Carbon Steel Carbon Hot Rolled Steel A 36 Steel Channel Angle Tee A 36 Structural Steel

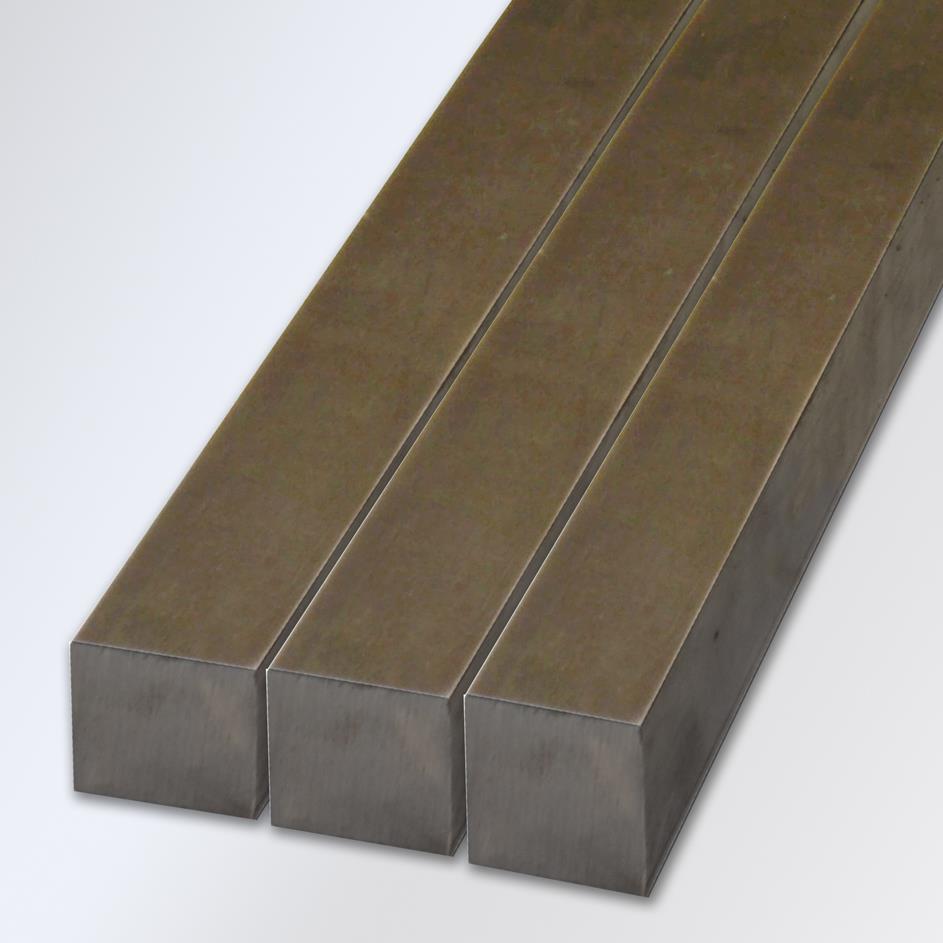

Cold Rolled 1018 Steel Square Bar Product Description 1018 is a free machining grade and is among the most commonly available grades in the world It is widely available in cold finished rounds, squares, flat bar and hexagons Despite its unimpressive mechanical properties, the alloy is easily formed, machined, welded and fabricated AISI 1018 hot rolled steel has significant mechanical properties, improved machining characteristics and has a high Brinell hardness measure Specific manufacturing controls are used for surface preparation, chemical composition, rolling and heating processesSteel GradesAISI 1018 Chemical information,Mechanical properties Physical properties, Mechanical properties, Heat treatment, and Micro structure AISI 1018 Physical Properties Tensile strength σb/MPa Yield Strength 23 σ 02 ≥/MPa Elongation 65 δ5≥ (%) ψ ψ≥ (%) Akv Akv≥/J HBS HRC 30 AISI 1018 Mechanical Properties

1

Aisi 1018 Steel Cold Drawn

1018 1022 1038 1045 1212 12L14 1215 1117 1141 1144 Type of Processing Hot rolled Cold drawn Hot rolled Cold drawn The mechanical properties shown are expected minimums for the sizes ranging from 3/4" to 11/4" REF SAE J1397 Rev May 1992 Conversions For Steel 56 60 65 71 76 81 85 90 95 100 105 110 114 117 1 122 125 1281018 steel round bar is a low carbon, medium manganese steel that maintains close dimensional accuracy This steel bar product has a smooth surface finish is machinable and displays excellent mechanical properties In addition, it is easy to weld, form, cut and machineUltimate Tensile Strength Yield Tensile Strength Imperial 0284 lb/in3 63,800 psi 53,700 psi Metric 787 g/cc 440 MPa

What S Cold Finished Steel Bar Product

Pdf Efficient Complex Surfactants From The Type Of Fatty Acids As Corrosion Inhibitors For Mild Steel C1018 In Co 2 Environments Semantic Scholar

Thermal Properties Metric English Comments;Hardness, Brinell 126 126 Hardness, Knoop 145 145 Converted from Brinell Hardness, Rockwell B 71 71 Converted from Brinell Hardness, Vickers 131 131 Converted from Brinell Tensile Strength, Ultimate 440 MPa psi Tensile Recommended for you RE Magnetic Permeability 1008 vs 1018 EdStainless (Materials) 31 Aug 17 2152 There will be a big difference The 1008 has lower C and lower Mn, which will increase max perm The Si level could also be a significant factor, lower is better for soft properties

A Guide To Carbon Steel Grades Plus A Chart

Basic Descriptions Of Making Carbon Alloy Stainless And Tool Steel P 4 Carbon Grades Types And Numbering Systems Glossary P Pdf Free Download

Forging of AISI 1018 carbon steel can take place in the range of °C (°F) Hot Working AISI 1018 carbon steel can be easily hot worked Cold Working Cold working AISI 1018 carbon steel will affect the hardness and mechanical propertiesSteel Grade AISI C1018 AISI C1018 This grade is produced in an electric arc or basic oxygen furnace and contains the greatest ductility of all carbon steel grades stocked in service centers Stocked in cold finished bars in a variety of shapes and sizes, its relatively low carbon, manganese, phosphorus and sulfur content make it a naturalWith higher manganese, 1018 is better steel for carburized parts, since it produces a harder and more uniform case It also has higher mechanical properties and better machinability due to the cold drawing process Most 1018 is produced by cold drawing

A36 Properties Pdf Steel Strength Of Materials

2

1018 cold finished steel is a generalpurpose, lowcarbon steel with good case hardening qualities It is especially suited to cold forming and bending operations 1018 is suitable for parts that require cold forming (such as crimping, swaging, or bending) For severe bends, however, stress relieving may be necessary to prevent crackingCTE, linear 115 µm/m°C @Temperature 0 °C 639 µin/in°F @Temperature 680 °F Typical steel 122 µm/m°C @Temperature 0000 300 °C 678 µin/in°F @Temperature 3 572 °F Typical for steel 139 µm/m°C @Temperature 0000 500 °C 772 µin/in°F @Temperature 3 4 beds, 25 baths, 2148 sq ft house located at 1018 Sun Poppy Ave, Las Vegas, NV 123 sold for $130,000 on MLS# * * BOM * * Charming two story home, with private desert

1018 Cold Drawn Steel Bar Supplier Cd 1018 Bar Eaton Steel Bar Company

China C1018 Spheroidized Annealed Cold Drawn Wire Coil Phosphate Coated Fastener Steel Wire China Metal Wire Chq Wire Rod

Standard Specification For Carbon Steel AISI 1018 / 10 Sheet Plate Standard AISI, ASTM, BS, DIN, GB,JIS Width 100mm – 3500mm Thickness 5mm – 3000mm Surface Finish PE coated, anti rust oiled, checkered, Galvanized, anti rust varnished, Black painted, color coated etc Hi All, I am trying to use carbon steel material that is certified as ASTM A on a Section VIII Div 1 vessel I've checked out thread Is A108 grade 1018 round bar a recognized ma by ASME (SA designation) and found some good info there The material certification I have only lists A108 and 9 in terms of specificationsAISI 1018 Steel, cold drawn Categories Metal ;

Carbon Steel Bergsen Metals Carbon Steel Distrubtor

080a15 1018 Bright Bar En3b Engineering Steel Impact Ireland Metals

Both 1018 and 10 steel are frequently purchased steel grades, many questions come up between the differences in 1018 and A36 steel particularly in the chemical makeup and the mechanical properties of the two different steel grades We thought it would be best to provide a comparison for A36 and 1018 steel that outlines those key differencesStandard mill sizes for Cold Rolled Steel C1018 Rectangular Bar range from 0125 X 0250″ all the way up to 3000 X 6000″ Other sizes may be available Contact your local Metal Supermarkets store to confirm availability and pricing, or buy online To buy online, find your desired size below and click on the applicable Continued SAEAISI 1018 steel is a carbon (nonalloy) steel formulated for primary forming into wrought products 1018 is the designation in both the SAE and AISI systems for this material G is the UNS number The properties of SAEAISI 1018 steel include two common variations This page shows summary ranges across both of them

Pdf Effect Of Different Quenching Media On Mechanical Properties Of Aisi 1018 Low Carbon Steel

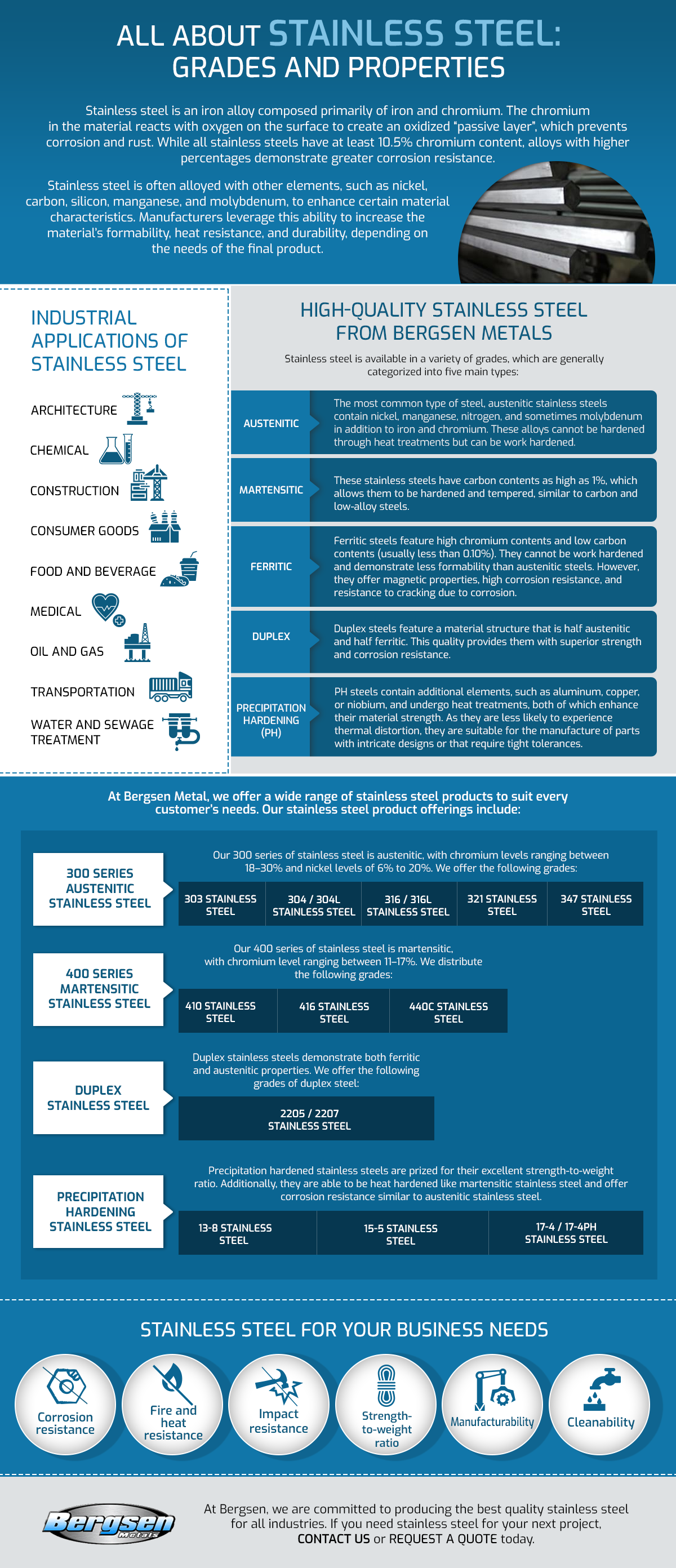

Stainless Steel Grades And Properties Bergsen Metal

1018 Steel Flat 1018 has a wide variety of applications It is used for parts requiring cold forming, such as crimping, swaging or bending For severe bends, stress relieving may be necessary to prevent cracking It is highly suitable for carburized parts, such as gears, ratchets, worms, pinions, pins, chain pins, dowels, machine parts, nonA lowcarbon steel, having higher manganese content than certain other lowcarbon steels, such as 10 Being richer in manganese, 1018 is a better steel for carburized parts, since it produces a harder and more uniform case It also has higher mechanical properties and better machining characteristics The hot rolled bars1018 Cold Drawn Steel Bar Cold drawn 1018 steel bar is a low carbon steel grade with good weldability and formability for a variety of applications Cold drawn 1018 steel is also available from a wide variety of mill sources However, due to its low alloy content, this grade has limits on mechanical properties

Cnc Steel Material Cnc Machining Steel Fictiv

Cnc Metalworking Manufacturing X 48 Inches 0 625 1018 Cf Steel Round Rod 5 8 Inch Raw Materials

It has a higher manganese content than certain other low carbon grades, such as C10 With higher manganese, C1018 is better steel for carburized parts since it produces a harder and more uniform case It also has higher mechanical properties and better machinability due to the cold drawing process Most C1018 is produced by cold drawing

Quality Cut To Size Cold Rolled Mild Steel Flat Bars Supplier In Los Angeles Ca Usa Bobco Metals

C1018 Aisi 1018 Cold Drawn Carbon Steel Square Flats Hex Bar China Cold Drawn Steel Bar Hexagonal Steel Bar Made In China Com

Dynamic Mechanical Properties Of Self Compacting Rubberized Concrete Under High Strain Rates Journal Of Materials In Civil Engineering Vol 33 No 2

Order 0 125 Mild Steel Round Bar 1018 Cold Finish Online Diameter 1 8

2

2

3 937 3 15 16 Inch 1018 Cf Steel Round Rod

Online Metal Supply 1018 Steel Round Rod Diameter 1 625 1 5 8 Inch Length 24 Inches Amazon Co Uk Business Industry Science

1018 Cold Finished Carbon Steel Bar Metal Rod

A Study Of The Corrosion Inhibition Of Mild Steel C1018 In Co2 Saturated Brine Using Some Novel Surfactants Based On Corn Oil Topic Of Research Paper In Chemical Sciences Download Scholarly Article

Grades Of Hot Rolled Steel Metal Supermarkets Steel Aluminum Stainless Hot Rolled Cold Rolled Alloy Carbon Galvanized Brass Bronze Copper

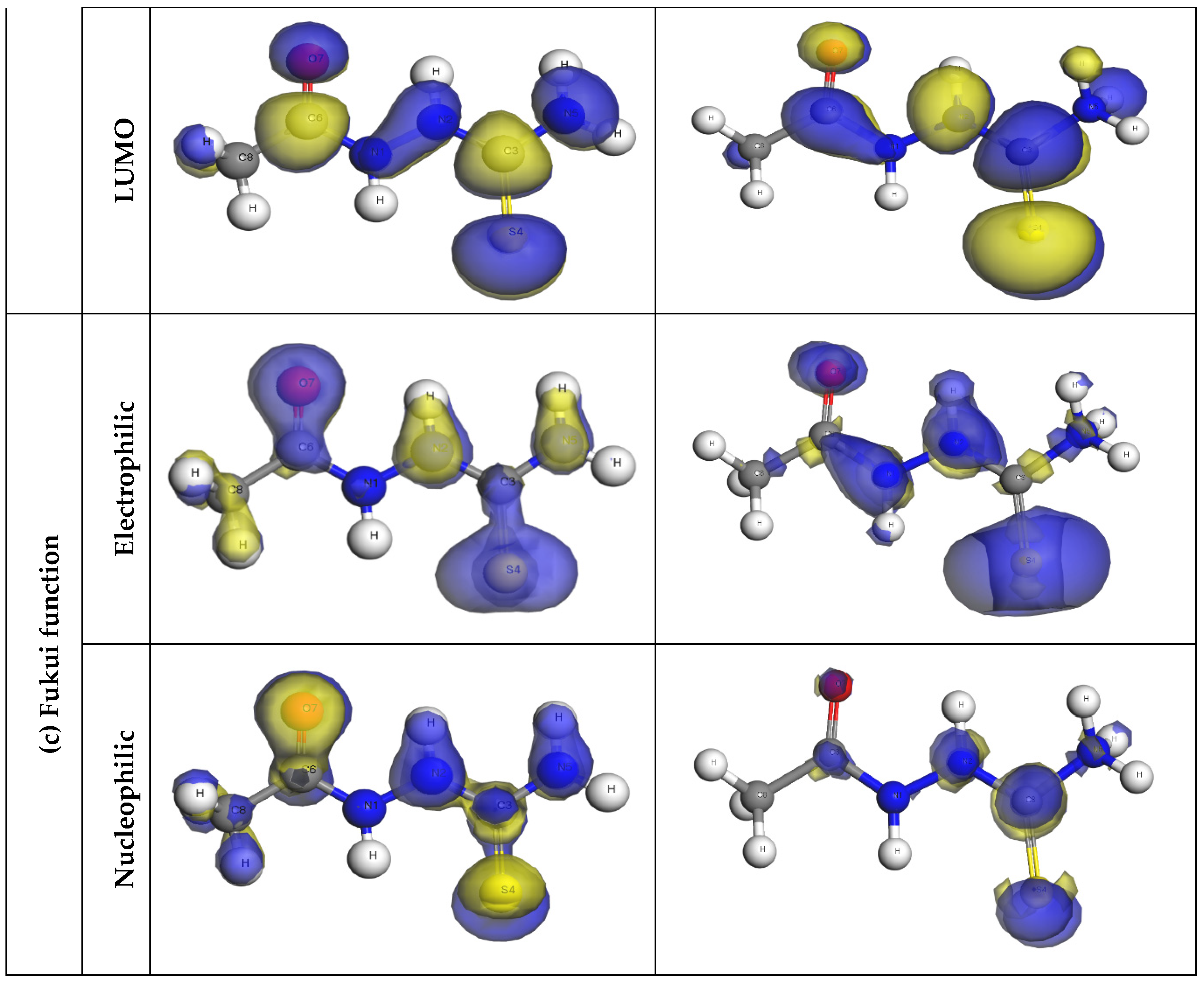

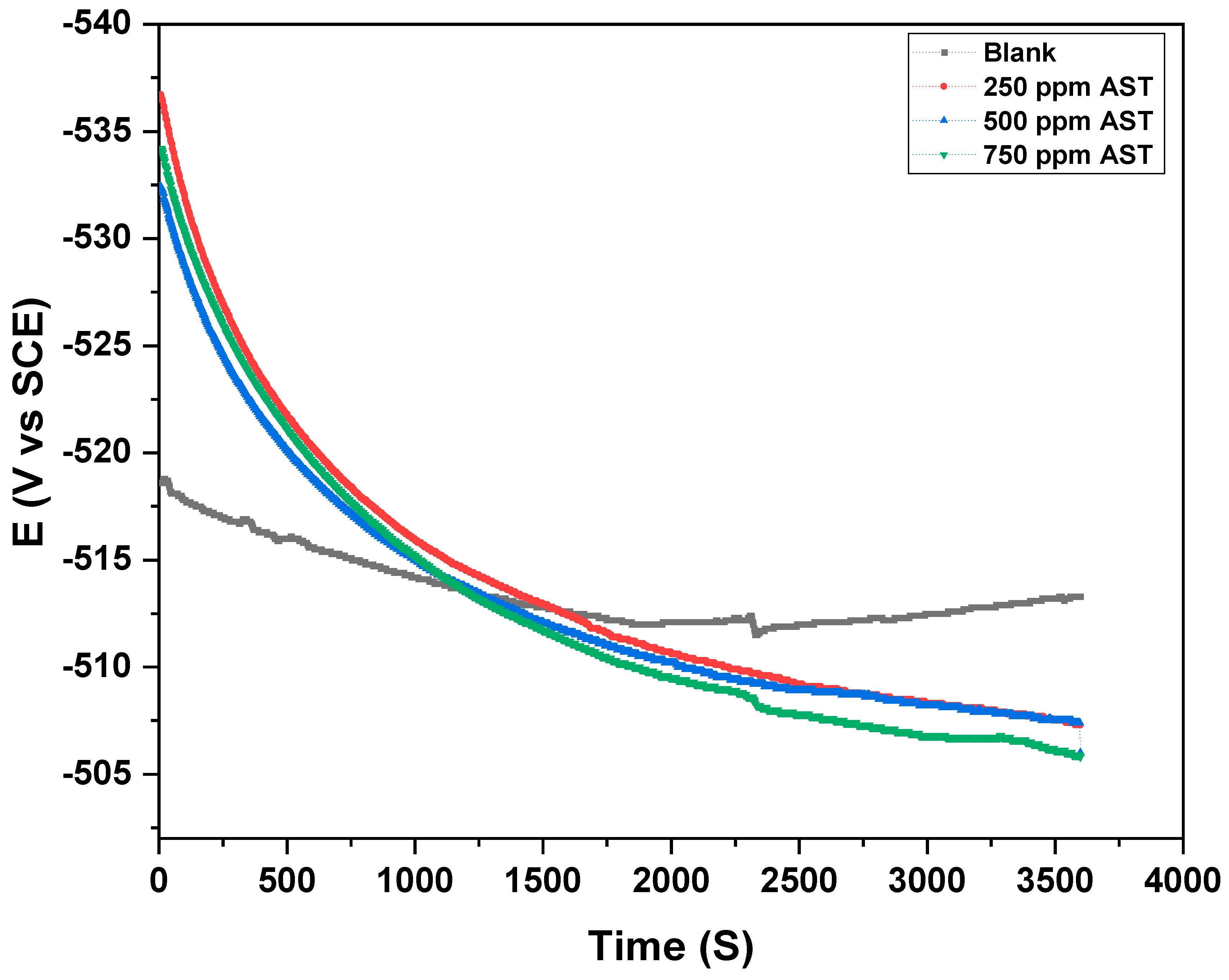

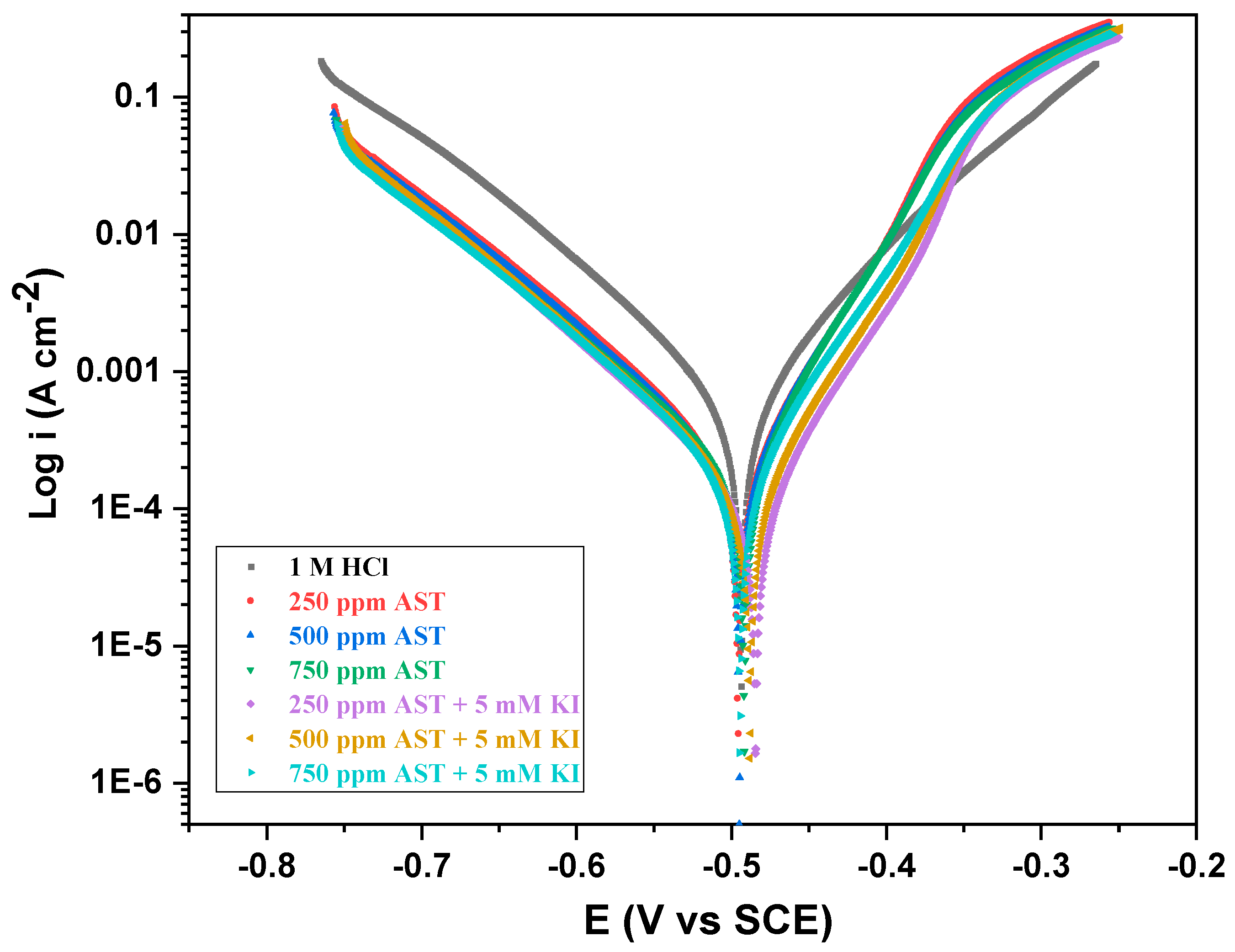

Materials Free Full Text Experimental And Theoretical Insights Into The Synergistic Effect Of Iodide Ions And 1 Acetyl 3 Thiosemicarbazide On The Corrosion Protection Of C1018 Carbon Steel In 1 M Hcl Html

Dlscrib Com Download Handbook Of Codes 5ac548dae2b6f5db258c3074 Pdf

Http Www Matweb Com Search Datasheet Pdf Quadrant Aspx Matguid 3a9cc570fbb24d119f08db22a53e2421

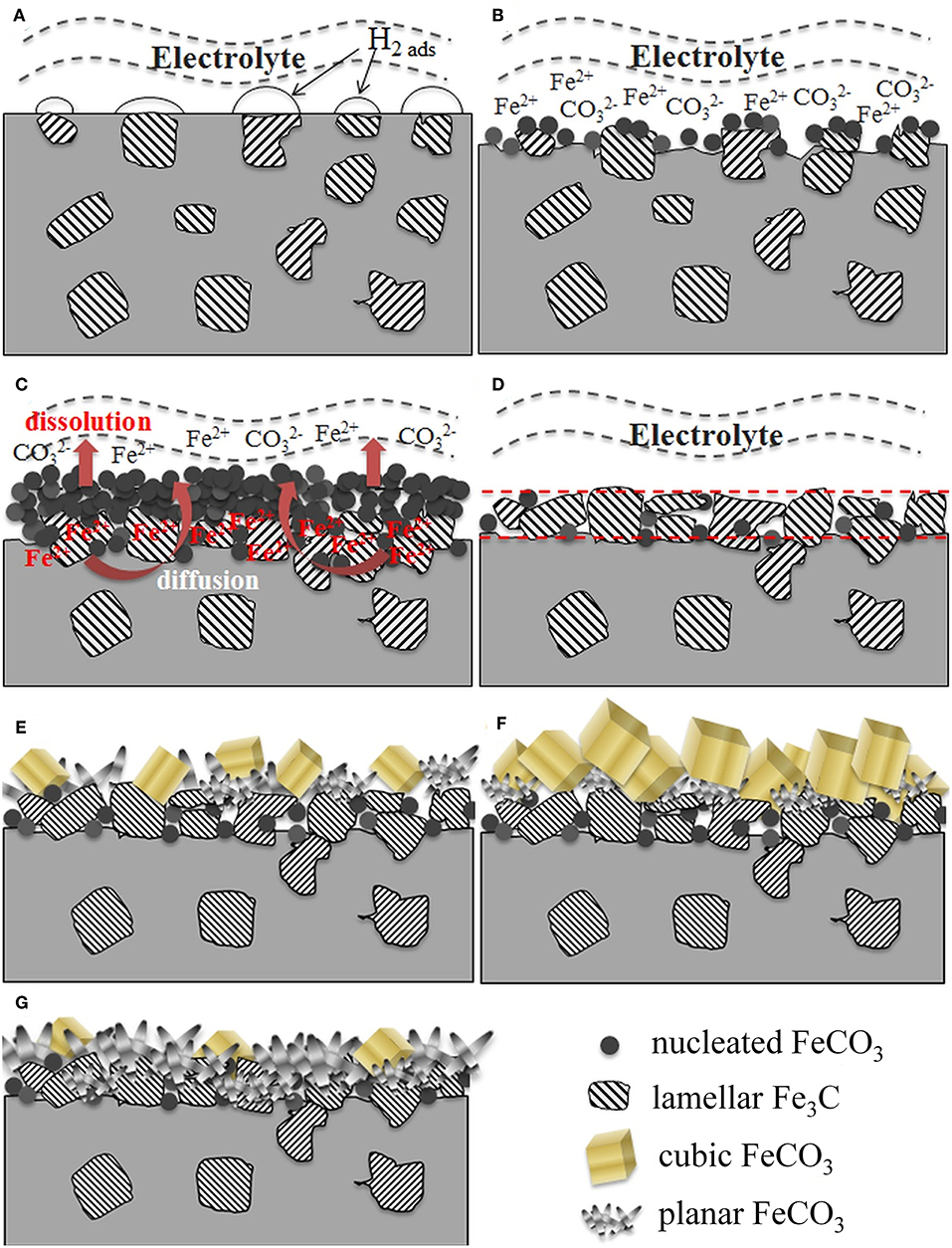

Frontiers Co2 Corrosion Of Low Carbon Steel Under The Joint Effects Of Time Temperature Salt Concentration Materials

9imxvj5qhgxcem

Www Ryerson Com Media Files Resource And Reference With Ryerson Logos Mechanical Properties S2312datasteelmechanicalpropertiesbarlogo Ashx

Sem Surface Fracture Of Cds Aisi 1018 After Tensile Tests At Different Download Scientific Diagram

Online Metal Supply 1018 Cold Finished Steel Square Bar 1 3 4 X 1 3 4 X 12 Long Amazon Co Uk Business Industry Science

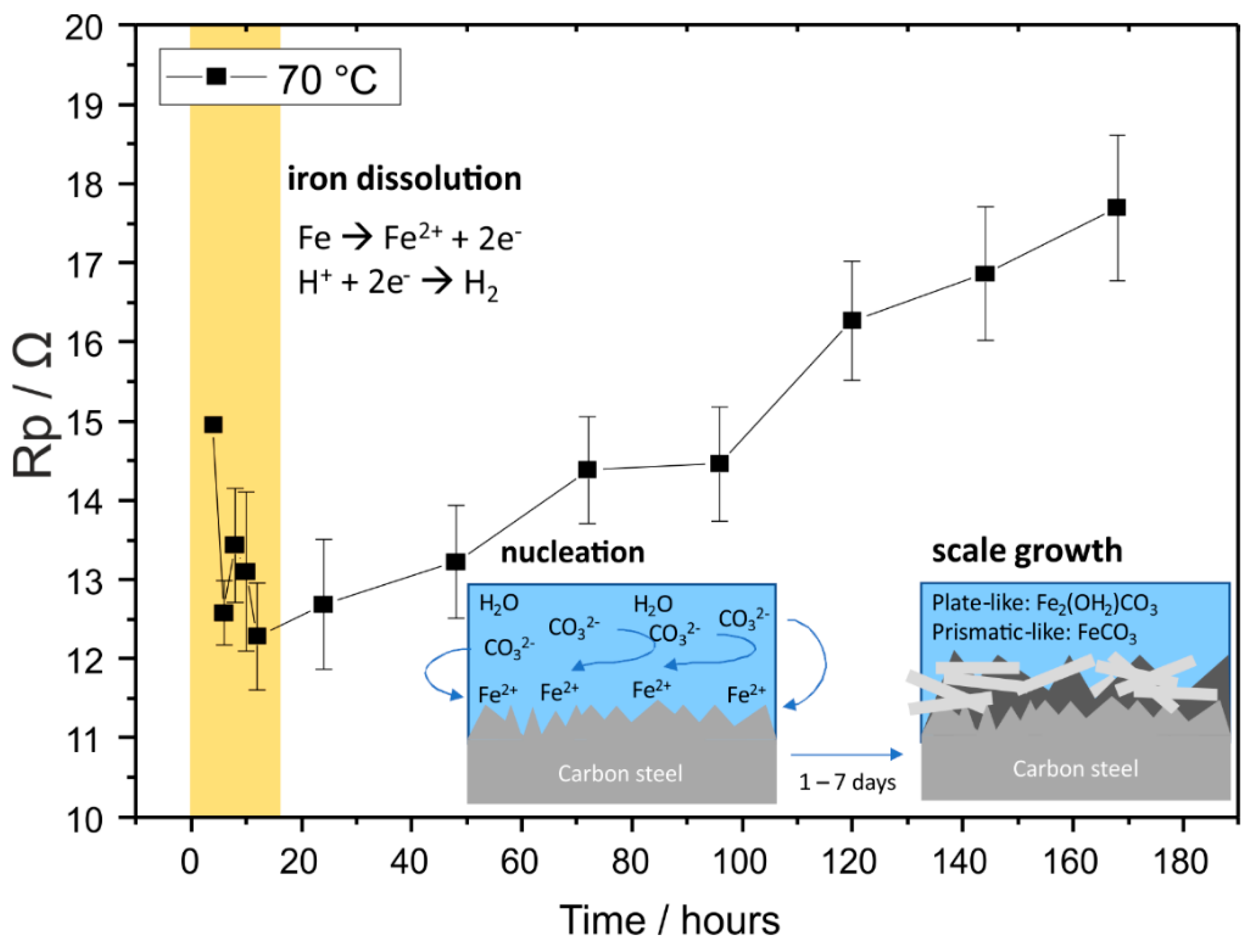

Materials Free Full Text Corrosion Of Carbon Steel In Artificial Geothermal Brine Influence Of Carbon Dioxide At 70 C And 150 C Html

Practical Machinist Largest Manufacturing Technology Forum On The Web

1

Dspace Mit Edu Bitstream Handle 1721 1 Mit Pdf Sequence 1 Isallowed Y

2

1018 Cold Roll Bearing Quality Alcobra Metals

Materials Free Full Text Experimental And Theoretical Insights Into The Synergistic Effect Of Iodide Ions And 1 Acetyl 3 Thiosemicarbazide On The Corrosion Protection Of C1018 Carbon Steel In 1 M Hcl Html

Www Huyett Com Getmedia Dc0731f3 D51b 4dad f8 4302f33daf Steel Making Basics Aspx

Metal Wire Selection Guide Alabama Wire Inc

Steel Grade Aisi C1018 Richmond Steel Canada

1018 Steel Properties

Www Encoremetals Com Assets Pdf Encore metals product manual 16 final Pdf

Pdf Experimental Investigation Of Mechanical Properties Of Cold Drawn Aisi 1018 Steel At High Temperature Steady State Conditions

Smooth Surface Used On Carburized Parts Astm A366 Cold Rolled Steel C1018 Buy Smooth Surface Used On Carburized Parts Astm A366 Cold Rolled Steel C1018 Roll Forming Steel Astm 66 Gr 4 Steel Flange

Low Carbon Flat Ground Stock Alro Steel

2

Http Eprints Whiterose Ac Uk 31 Macrh Pdf

Pdf Microstructure And Mechanical Characterization Of Austempered Aisi 1018 Steel

Amazon Com 1018 Cold Roll Carbon Steel Rectangular Bar Unpolished Mill Finish Cold Finish Astm 108 0 125 Thickness 0 25 Width 84 Length Onlinemetals Industrial Scientific

Heat Treatment Of Bolts Fasteners Purpose Of Heat Treatment Bayou City Bolt Supply

Astm A36 Mild Steel Strength Of Materials

Astm A36 Structural Steel Properties Nm500 Steel Stocklist Exporter

A36 Steel A36 Steel A36 Steel Plate Kloeckner Metals Corporation

Weldability Stafford Manufacturing Corp

Design With Steel Dimensions Properties Handbook By Steel Tube Issuu

China Screw Wire C1018 Cold Heading Quality Saip Annealed Phosphating Drawn Steel Wire China Wire Rod Sae1018

Novel Naphthenate Surfactants Based On Petroleum Acids And Nitrogenous Bases As Corrosion Inhibitors For C1018 Type Mild Steel In Co2 Saturated Brine Topic Of Research Paper In Chemical Sciences Download Scholarly Article Pdf

1018 Cold Drawn Steel Bar Supplier Cd 1018 Bar Eaton Steel Bar Company

080a15 1018 Bright Bar En3b Engineering Steel Impact Ireland Metals

Materials Free Full Text Experimental And Theoretical Insights Into The Synergistic Effect Of Iodide Ions And 1 Acetyl 3 Thiosemicarbazide On The Corrosion Protection Of C1018 Carbon Steel In 1 M Hcl Html

Iso Shear Connector Weld Stud Steel Shear Stud Building Material C1018 Buy Iso Shear Connector Weld Stud Steel Shear Stud Product On Alibaba Com

Q Tbn And9gcsvhuusekokgta9xwuc8skb9fivh5ob3kfexc5rphnjw8vtaeob Usqp Cau

Www Osti Gov Pages Servlets Purl

Http Www Uwyo Edu Ceas Resources Current Students Classes Meref Example Long Report Pdf

Pdf Example Long Laboratory Report Mechanical Properties Of 1018 Steel In Tension Semantic Scholar

Q Tbn And9gcsvhuusekokgta9xwuc8skb9fivh5ob3kfexc5rphnjw8vtaeob Usqp Cau

Astm A36 Mildlow Carbon Steel Steel Strength Of Materials

In Stock Wholesale Pickled Oiled A 36 Steel Angle

Http Lin12 Triumf Ca Text Elinac Quads Steel Magnetic Properties Pdf

Metal Alloy Round Rods Metals Alloys 1018 Cf Steel Round Rod 11 16 Inch 0 687 X 48 Inches

Http Eprints Whiterose Ac Uk 37 Paper2 Pdf

Processing And Mechanical Properties Of Macro Polyamide Fiber Reinforced Concrete Topic Of Research Paper In Economics And Business Download Scholarly Article Pdf And Read For Free On Cyberleninka Open Science Hub

C1018 Aisi 1018 Cold Drawn Carbon Steel Square Flats Hex Bar China Cold Drawn Steel Bar Hexagonal Steel Bar Made In China Com

Basic Descriptions Of Making Carbon Alloy Stainless And Tool Steel P 4 Carbon Grades Types And Numbering Systems Glossary P Pdf Free Download

7 Things To Consider When Choosing A Carbon Steel Grade

Dspace Mit Edu Bitstream Handle 1721 1 Mit Pdf Sequence 1 Isallowed Y

080a15 1018 Bright Bar En3b Engineering Steel Impact Ireland Metals

2

2

Microbial Communities Of Orange Tubercles In Accelerated Low Water Corrosion Applied And Environmental Microbiology

Steel 1018 Machined Parts C1018 Machining Properties Ptj Shop

Pdf Microstructure And Mechanical Properties Of Cold Rolled Aisi 1018 Low Carbon Steel

Pdf Example Long Laboratory Report Mechanical Properties Of 1018 Steel In Tension Semantic Scholar

Aisi 1018 Carbon Steel Uns G Pdf Txt

C1018 Aisi 1018 Cold Drawn Carbon Steel Square Flats Hex Bar China Cold Drawn Steel Bar Hexagonal Steel Bar Made In China Com

Amazon Com 1018 Cold Roll Carbon Steel Rectangular Bar Unpolished Mill Finish Cold Finish Astm 108 1 5 Thickness 3 Width 60 Length Onlinemetals Industrial Scientific

Dependence Of A Mechanical Strength And B Elastic Modulus On Download Scientific Diagram

Carbon Steel Aisi 1018 Bright Bars Aisi 1018 Cs Round Bar Carbon Steel Aisi 1018 Flat Bars Manufacturer Supplier Stockists

Astm A36 Mildlow Carbon Steel Steel Strength Of Materials

0 件のコメント:

コメントを投稿